Packed tower aeration water treatment stands as a cornerstone of water purification, offering a comprehensive solution for contaminant removal. This in-depth exploration delves into the mechanisms, applications, design considerations, and operational aspects of this essential technology, empowering readers with a thorough understanding of its significance in water treatment.

Packed tower aeration systems harness the principles of mass transfer to effectively remove impurities from water. The intricate design of these systems, coupled with the strategic selection of packing materials, optimizes gas-liquid contact, enhancing the efficiency of contaminant removal.

Packed Tower Aeration System Overview

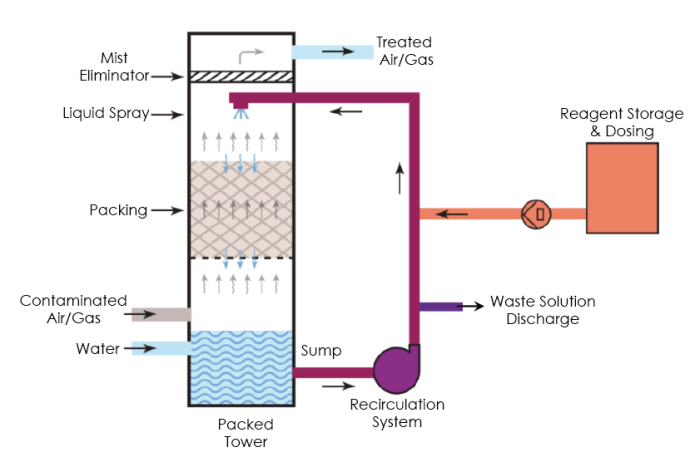

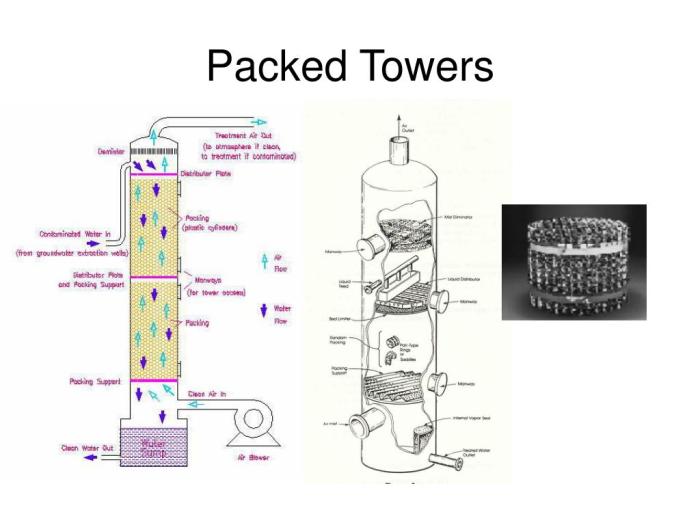

Packed tower aeration is a water treatment process that utilizes a packed column to facilitate the transfer of oxygen or other gases into water. This process is commonly employed to remove dissolved gases, such as carbon dioxide or hydrogen sulfide, or to oxidize contaminants like iron and manganese.

A packed tower aeration system consists of a vertical column filled with packing materials, which provide a large surface area for gas-liquid contact. Water flows downward through the tower, while air or another gas is introduced from the bottom and flows upward counter-current to the water.

As the gas and water come into contact, mass transfer occurs, resulting in the removal or addition of dissolved gases.

Mass Transfer Mechanisms

The mass transfer process in packed tower aeration is governed by several mechanisms, including:

- Convection:Mass transfer occurs due to the movement of gas and liquid relative to each other.

- Diffusion:Dissolved gases diffuse from areas of higher concentration to areas of lower concentration.

- Chemical reaction:In the case of oxidation processes, chemical reactions between dissolved contaminants and oxygen facilitate mass transfer.

The efficiency of mass transfer is influenced by factors such as the packing material, flow rates, and temperature.

Applications in Water Treatment

Packed tower aeration is widely used in various water treatment applications, including:

- Iron and manganese removal:Packed tower aeration oxidizes dissolved iron and manganese, converting them into insoluble forms that can be removed by filtration.

- Hydrogen sulfide removal:Packed tower aeration removes hydrogen sulfide from water by stripping it into the gas phase.

- Carbon dioxide removal:Packed tower aeration is used to degas carbon dioxide from water, which can be beneficial for reducing corrosion in pipelines and equipment.

Design Considerations, Packed tower aeration water treatment

The design of a packed tower aeration system involves several key parameters:

- Packing height:The height of the packed bed determines the contact time between the gas and water.

- Packing diameter:The diameter of the packing materials affects the pressure drop and mass transfer efficiency.

- Flow rates:The flow rates of gas and water must be carefully controlled to optimize mass transfer.

- Packing materials:The selection of packing materials is crucial for maximizing gas-liquid contact and mass transfer efficiency.

Operation and Maintenance

Proper operation and maintenance of packed tower aeration systems are essential for optimal performance:

- Monitoring:System performance should be regularly monitored, including flow rates, pressure drop, and dissolved oxygen levels.

- Troubleshooting:Common problems include clogging, scaling, and foaming, which can be addressed through appropriate maintenance measures.

- Maintenance:Regular maintenance includes cleaning the packing materials, replacing worn parts, and adjusting flow rates as needed.

Quick FAQs: Packed Tower Aeration Water Treatment

What is the primary purpose of packed tower aeration in water treatment?

Packed tower aeration primarily serves to remove dissolved gases and volatile compounds from water through the mass transfer process.

How do packing materials contribute to the efficiency of packed tower aeration systems?

Packing materials increase the surface area available for gas-liquid contact, enhancing the mass transfer rate and improving the removal efficiency of contaminants.

What are the key design parameters to consider for packed tower aeration systems?

Critical design parameters include packing height, diameter, and flow rates, which must be carefully determined to optimize system performance and achieve desired treatment outcomes.